|

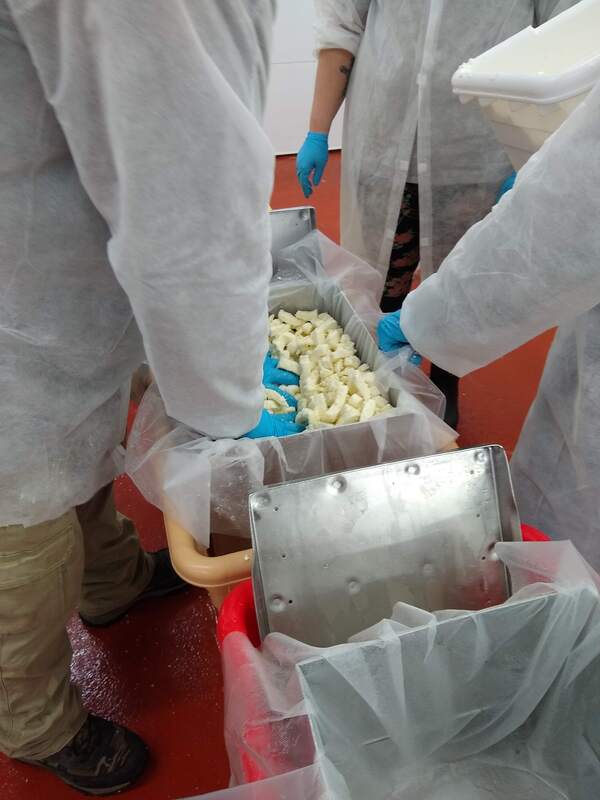

Cheddar Cheese. Probably one of the most well known and popular cheese types in the world. Cheddar cheese has a slightly nutty flavor and a semi-hard texture. The longer cheddar cheese ages the "sharper" it tastes. For some mild cheddar is perfect and others prefer the sharpiest they can get (that would be me)! Many varieties of cheddar that are produced have added food coloring to make the cheese color more consistent, but cheddar cheese is naturally off-white. So all those pretty orange/yellow blocks of cheddar cheese you see... food coloring! We skip this step and let the pretty off-white color of the natural cheddar shine. So, how do we get from cow's milk to those delicious cheese slices on your crackers. Well let's find out! As with all cheese you need the raw ingredients to start. Milk comes in from our farms and is delivered three or four days a week. The only other ingredients used are rennet, enzymes and salt! After the milk arrives to our creamery it is pasteurized. Our pasteurizer is high-temp, short-time or HTST. Our milk is heated up to 162F for 15 seconds. HTST pasteurization is great because it kills all the potentially bad bacteria that could make you sick in the milk, but it doesn't heat it high enough to denature proteins of change the structure of the milk. This means there is minimal, if any, change to the flavor of the milk and keeps it as close natural as possible. After pasteurization milk is pumped into our cheese curd vats, enzymes and rennet are added, and the milk is cooked until a curd forms. The cheese is then cut with large knives and the whey is drained from the vats. The cheese forms a large mat of cheddar that is cut into smaller chunks. These chunks are stacked and flipped multiple times (this is known as cheddaring). The acidity of the whey draining off is tested. This test tells us when to flip and when to stop the cheddaring process. When the cheese is done it is time to mill and salt. Salting the cheese enhances the flavor, pulls moisture out and also can help regulate microbial growth. The curds are stirred in the cheese vat to make sure they are coated evenly with the salt and then the fun of pressing cheese begins! Cheese curds that are going to be turned into cheddar are weighed out to ensure the correct amount is packed into the cheese forms. The forms are lined with cheese cloth and filled with cheese curds. Usually, we fill the molds up, squeeze the curd down and then pack the last five pounds in by hand. The cheese cloth is folded over the curd and the lid goes on! Cheese forms get placed on the cheese press and squeezed down. The pressure from the cheese press removes excess whey and causes the curds to knit back together into a large block of cheese. After the blocks have been pressed they are removed from the forms, placed into bags and vacuum sealed shut. Then our 40 pound blocks of cheese are placed on the shelf to age. Cheddar ages anywhere from 30 days to 8 years. The oldest aged cheddar that we have is 2 plus years old! Looking to learn more about our cheese and want to check out our processing plant? Come visit and set up a tour! You can find all our cheeses (and more) on our retail store shelves and specialty shops around the tri-state area. If you can't make it in, shop online and have our block cheddar and cheese curds delivered straight to your front door.

2 Comments

Leave a Reply. |

WW Homestead Dairy Team

We love cows, curds & ice cream!!! Archives

June 2023

Categories

All

|

Summer Hours

|

Telephone563-568-4950

|

|

RSS Feed

RSS Feed